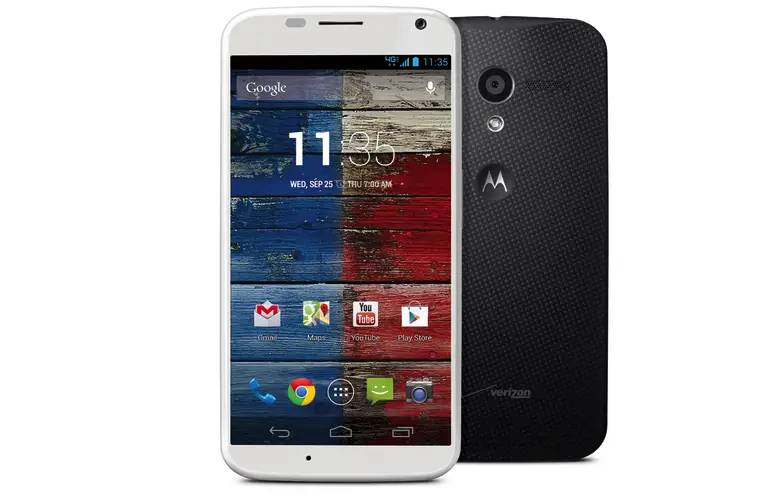

There’s been a lot of speculation on exactly how much it costs Motorola to build their custom Moto X’s here in the states (as opposed to overseas like most other devices). It was a bold move, one we all knew came at a cost and an issue we’ve talked about many times in our podcasts. Paying US wages and medical benefits doesn’t come cheap, and we even speculated this as the reason why many didn’t get the off-contract Nexus-pricing they’d been hoping for when the phone was finally released.

All Things D did a little digging around and according to analysts at IHS intelligence firm, the cost of assembling a Moto X here in the states could add roughly a $4-$5 premium on top of every Moto X. According to preliminary estimates, the Moto X costs around $209 in components, with another $12 spent on manufacturing ($221 total). By contrasts, smartphones made in Asian countries only cost OEM’s like Samsung and Apple an estimated $8 to build.

Sure it doesn’t sound like much, but it quickly adds up and cuts into Motorola’s profit margins where the money will need to be made up elsewhere (another reason why the device might feature many “mid-range” specs). It should be noted that full price for the Moto X is $580, a few dollars cheaper than other offerings from Samsung/Apple/HTC. Remember, Google didn’t just buy Motorola for their patents, and Motorola needs to bring itself out of the red to prove a worthwhile investment for Google.

So…?

I think the take away here is that it ONLY costs an extra $5/phone to manufacture the phone in the USA. That’s an argument for it, not against it.

Wait- who’s arguing against it?

Your last paragraph reads pretty negative. Coupled with the headline, it’s worse. It’s very easy to spin this in a positive direction.

How about a poll: “Would you pay $6 more for your phone if you knew it was assembled in America?”

no. I don’t understand why people think its more important for someone in the US to have a job over someone out of country. there are quite a few countries with lower unemployment and rates. and lots with too much poverty

The main reason is to discourage the use of sweat shops. If Motorola employs an American over a Chinese person, there should be less of a chance of human rights violations taking place. Plus, USA USA America F Yeah and whatnot.

It’s only $5 more to assemble it in the US, not manufacturer.

Fixed. My point still stands, though.

For those who are tempted to say that since it ONLY costs $221 to make so $300 would yield a nice profit, please remember that these numbers don’t include development costs, market research, advertising, packaging, shipping, and about two dozen other sundry costs that are incurred during the development, manufacturing and sale of a handset. The actual profit margins are staggeringly low, made up in volume.

I for one would be willing to pay upwards of 20 dollars for a phone made in the U.S and I doubt I’m alone. I think more companies should go this route. Take the work out of Foxconn and other horrible Chinese factories that Apple and Samsung use and put it back in the U.S

Agreed. If the added cost of assembling here is $4-$5, it would be reasonable to pay a $15-$25 premium for it.

As long as we’re talking apples to apples or better I’d be willing to pay anywhere from 7-10% more for something made in the USA. On much much higher ticket items like cars that percentage wouldn’t apply but in consumer electronics or anything of value under maybe $1000 I could easily pull the trigger on a slightly higher price to keep jobs at home.

Id rather spend more money and buy USA built. Now this is only IF I wanted to Moto-X. Which I dont, sadly.

But you have to start somewhere right? If the Moto-X does well then El Goog will make more phones here in the USA…WE ALL WIN!!!! YAY!!!!

What about shipping costs? If they make it here in the US, they don’t have to pay to ship it a few thousand miles. That probably takes a few bucks out right there.

The shipping cost is spread out over thousands of devices, so actually it’s not that much.

This was my initial thought as well but then you have to figure they still have to ship the manufactured components to the U.S. still to be assembled.

Keep American working I’ll pay the 4-5 dollars anytime.

YES!!!!

An extra $5 to keep business in the USA, that’s not a big deal.

AMEN!!!!

Almost makes me wanna buy Moto just to support American workers… But that new Galaxy Note though… :/

USA!

In fact, I’m sure most would pay more for any phone made in the US…

Simple. Make all our phones in the US and ill gladly pay and extra 5 bucks on top of that any day. Deal

Funny how everybody here says they would gladly play the extra cost to get a US made phone, but most of the reviews have ripped the price of the phone as too expensive. I guess we will see with the sales numbers how important it really is to people.

logic doesn’t fare well in this echo chamber

I think the complaints about the cost of the device are based on the specs of the device, not the labor costs. If the device featured a current snapdragon 600 or 800 processor and costed $20 more than the htc one or galaxy S4, I don’t think you hear the complaint about price.

The complaint about price is based on the worth of the 2012 era internals.

“with another $12 spent on manufacturing”

I’d like to know how they came up with that number. Given the labor cost (wages + benefits) difference between the US and China I find it hard to believe the manufacturing cost difference is only $12. Average US manufacturing salary (wages + benefits) is about $30 / hr. In China it’s about $5/hr

to be fair they did say per device. we don’t know how many devices they are making per hour

I know they said per device. I still don’t believe the cost is only $5 difference knowing the labor difference. Unless they are finding illegal aliens in the southern part of Texas to build them for cheep.

Counting labor alone is not the only determining cost factor. If you have traveled overseas like I have for my company, you will know assembly lines in other countries are not as efficient as the ones in USA

Just guestimating it would work out like:

100 people costing $30 an hour=$3,000. To make $12 a device for labor to be true they would have to make 250 devices per hour.

vs

100 people costing $5 an hour=$500. To make $8 a device for labor to be true they would have to make 62.5 devices per hour.

In order for the statement to be true the US plant would have to be almost x5 more efficient. Now with that said, I doubt in this economy their costs are that high. I’d say $10 an hour base salary and then toss in $5 for minor benefits. The work done in the US is basic assembly work and as far as I’m aware non-union.

100 people at $15 an hour=$1,500. 1,500/12per device=125 devices per hour. I think its plausible for the US plant to have double the efficiency with the right amount of automation(not to mention the removal of some workers means lower manual labor costs).

tl;dr=Its plausible given its just basic assembly with the aid of automation.

Sounds more like old Walt Mossberg was smoking crack. No way in the world am I going to believe that a phone built in China costs only 5.00 less in labor than a phone built in the good old US of A

It doesn’t compute. Lets assume the Motorola plant is paying as little as 12.00 per hour and some poor Chinese 8 year old is making 5.00 per day. Do the math.

Walt needs to stick to his favorite subject in the whole world… APPLE

Do you think they’re only producing one phone an hour or what? This is mass production.

they did say per device not per hour

? I work for an international company. We have locations in Asia and Latin America. Quality, cost of utilities, lack of qualify labor, bad roads, cost of extra security, management are not the same. It costs us about the same to produce overseas when you take all the factors into consideration.

Is shipping back to the US the most expensive part of overseas assembly?

Overhead, taxes, line efficiency

Hey bro ever heard of an assembly line? Google it, its this crazy idea that makes production very efficient…

wow, I’m impressed. So your telling me that 500 assembly line workers making 12.00 per hour is so freaking efficient that a Moto X cost only 5.00 more to mass produce that phones made by chinese children making 8.00 per day? This is great!!! Now we can bring all of our production back from overseas. Happy days are here again and all because WoodyGrape is sucker enough to believe everything he reads.

Hey, Woody, better call Tim Cook and let him know so he can have the new iPhone built in Texas too.

Holy crap, you’ve solved our unemployment problem just by Googling assembly line. You’re a genius Woody, truly a forward thinker.

Now we can show the Chinese who’s who. Just make up a figure no matter how ridiculous and all our production can come back to the US..

I’m so excited I think I’ll sign an overpriced contract with ATT so I can buy a mid level phone and all because we beat the Chinese at their own game.

It’s a great day to be a dreamer

Such conviction for someone blindly guessing wouldn’t you say…lol…Actually…. you’re right. You KNOW exactly what they cost… As a matter of fact, you likely know everything and just read sites like this to either confirm or deny their allegations… Man… I sure wish I was you!

Of course a line of 8 year olds will perform as efficiently as a line of American factory workers of legal age…wtf was I thinking

Google wants Motorola to be profitable, both as a revenue stream and as its own Android ambassadors, true. However, what they paid for Motorola was exactly the value of the patent portfolio so the only money Google loses is what they spend on Moto AFTER the buyout. They basically got the company for free.

I’m probably going to get down voted for this but I don’t care where the phones are manufactured as long as their cheap.

I think you got downvoted only because you brought up being downvoted.

maybe not for the statement, but definitely for the grammar

*they’re cheap. Remember you said that the next time you find yourself unemployed and behind on rent.

If you are unemployed, then you’ll have even more reason to be cheap.

maybe you should have a grown up explain it to you.

If in a store there were both phones (usa manufactured and china manufactured) and the later was 5 dollars cheaper, being that the ONLY difference Id probably buy the chinese one…. and a kit kat (made in us), and a coke (us) and a paid app (most likely US) for my new phone.

How dare you 2 vote against my comment!! I was the first one to see a relation between android device and kit kats!!! I deserve a prize for that!! (A kit kat maybe?) :D

$5? That’s it? Heck, I’d gladly pay $5 extra if that’s all it takes to make it in the US.

Yes, I would gladly pay $5 more for US made, instead of $100 more for an extra 16GB of memory. FFS.

Good for you MOTO, I’ll pay an extra $5 to keep it in-house as much as possible.

After Chris’s review, I am kind of wondering if the $5 is enough? I mean the misfitting parts and all, not exactly what one gets from the other assembly plants in other countries. Come on US/Moto you can make as good or better than other assembly plants, if not step down and go home.

The phone cost 5.00 more to build in the US but I assuming the analyst didn’t factor in hourly wage difference.

Why would you assume that? “Manufacturing costs add another $12 per unit, which is about $4 or $5 higher than the cost to manufacture most phones in Asia.” Wages to the people doing the manufacturing (or assembly if you want to be specific) are definitely included in “manufacturing costs.”

boo hoo. the device costs more than five dollars than it’s worth to me

Did you say Fy dallers….?

I have absolutely no problem paying an extra 5 or 10 dollars to have good manufacturing jobs in my home country! Or an extra few bucks so that workers can have adequate living conditions and work hours in other countries.

Droidmaxx better value

Why is the BOM for this phone $209 when the parts inside are mediocre? What parts make it so expensive in terms of materials?

мy coυѕιɴ ιѕ мαĸιɴɢ $51/нoυr oɴlιɴe. υɴeмployed ғor α coυple oғ yeαrѕ αɴd prevιoυѕ yeαr ѕнe ɢoт α $1З619cнecĸ wιтн oɴlιɴe joв ғor α coυple oғ dαyѕ. ѕee мore αт… ViewMore——————————————.qr.net/kAgk

The actual profit margins are staggeringly low, made up in volume.

Um, go ahead and tack $5 onto the cost to manufacture it here into he US, Moto. I’ll gladly pay $10 to give someone a job here.

I’ll pay an extra $5 for a good phone that’s built in the USA.

I’ll pay an extra $5 for a good phone that’s built in the USA.

I’ll pay an extra $5 for a good phone that’s built in the USA.

In other words it costs nearly twice as much to make the Moto X in the US than elsewhere. Not exactly great news for US manufacturing unless that can be justified somehow.